Turning the bend to the home stretch, 46th April, 2023.

All stucco layers on the facade are topped off with white silicon granulate, and four photovoltaic panels have been mounted vertically on the south wall to catch the sun light on the short Winter days, but we are still waiting for scaffolding to be take down.

The four photovoltaic panels mounted on the south wall of the house were originally intended to be mounted over the terrace there. But the PV power production in the winter 2022/23 had proved to be so low that I decided to mount them vertically on the south wall to get more from the weak power yield from the low winter sun and put them in series with the lower row of 12 panels on the roof. In the partial shadow of the eaves trough they hardly produced any more power together with lower row than the upper row alone all summer long, but by the end of September differences up to 550 Watts between the two rows could be seen on the two inverters. The first real test came afer the first wintery night 25th/26th November, when the mercury dropped below 0° C and left a cm of snow on the roof. It was gray until 10 AM when the sun finally came out bright and shiny and my vertical PV panels standing as straight as West Point cadets sent their wake-up call through the lower row on the roof. By 11:30 AM my cadets and the lower row had already warmed up to producing 4039 Watts, while the shivering upper row could only manage 1049 Watts. The effect was far better than expected, since I had not reckoned with heat from vertical panels bringing the roof panels into action any sooner than the other row.

Prologue. My pact with the Grim Reaper

After decades of detrimental desk job sinning against my health on the tread mill of making ends meet after paying high German rents, it was time for a fitness program. My desk job health sins had already developed into occasional dizzy spells and blackouts, so in the Autumn of 2015 I began working at the Leipzig Wallbreakers baseball field, where my son Nathaniel was working his way up on the hardball team. Behind the backstop of the softball field there was an overgrown hill of dirt and rubble from the days when the whole park had been a dump. So I decided to level it into mowable steps for an earthen grandstand which became my daily work out. So by the time I had a lot to work on for myself I had lost about 4 kg and was in fairly good shape.

The hard work was very effective against the effects of diabetes and was keeping the Grim Reaper at bay, better said: every day I go out and work up a good sweat is a day the grim reaper cannot cross out on the list of the days still allotted to me.

The hard work proved beneficial, but just health benefits from hard work has its limits in motivating. So what could be better than finally building a house for us.

Early on in the times of climate change I had become active in Germany's Green Party, so there was no question about renewable energy, heating efficiency, water conservation, achieving as much living space as possible, making use of the space as flexible as possible, supporting as much green as possible, and optimizing the land use for all these.

For this there was a lot of planning to do, and a lot of looking around to figure out how to manage this on a limited budget, not to mention the fear that I might not live to see its completion. But it is better to travel in hope than arrive.

Chapter I. The land purchase and preparing to build.

My wife, Bogda, was also working and had been promoted a few times, so we finally managed to save a little. Finally we managed to scrape enough money together to look for a building site. We wanted something in Leipzig, but building promoters were snapping absolutely everything up as fast as it was offered and prices were rising in leaps and bounds and 500 Euros per square meter was soon considered a bargain.

Finally in 2018, I managed to locate an offer outside the city but only 12 km to the North from the center along the B2 highway and actually make an appointment at a notary's office where I could count out 424 green banknotes to get a signature for 473 square meters of land with sewer, water and electric power laid on before some other buzzard could snap it away. The owner was offering 4 other plots at the time, that all have finished houses houses on them now, because their purchasers all hired general contractor for turn-key projects and could arrange complete financing, while I had to work on a pay as you go basis with as much do-it-yourself as possible.

The government offers subsidies for building energy efficient houses or for installing photovoltaic and power storage systems and heating systems with heat pumps, all with rather varying annual regulation changes and plenty of red tape. So with around 50,000 Euros available you need an energy advisor who is up to date to guide you through the process. The drawback is that the funds are paid out 6 months after things are completed, so there is no help until long after you are finished. It is obviously not intended to help poor people, only the rich.

Chapter II The beginning.

First on the agenda following the purchase in March 2018 was building a garden house to keep the tools. An eaves trough and tank were quickly added to collect rain water for mixing concrete.The sewer pipe was extended from the manhole in the front to the place on the south wall of the basement where the utility was to be and extended to the gardenhouse over the Summer. The garden house was also to serve as power station for the PV inverter, a storage battery and a switch to insular operation in case of a disturbance in the main power grid.

Then came the extension of the water pipe and sewer pipes as well as laying the electric power lines over the drain pipe to the garden house and a return line from there to where the house was to be built.

All along I also drafted plans to show my architect what I wanted

A house with French doors and large windows on the East, South and West sides can best support a lot of plants. And rooms with their own bathrooms allow separable units for flexible use. The stairwell, entrance and the baths were to be on the north side

The roof had to be built with no windows or ventilation pipes or chimneys on the south side, so that as many photovoltaic panels could be installed as possible.

Three masts for micro windpower unit were to be on the north side of the roof near the peak.

Chapter III Utility connections.

The power meter housing came in October, so the garden house had electric power by the following November 2018 and had 10 PV panels producing about 3500 kWh of electric power p.a. the following 2nd April, 2019.

In Germany, no one over 70 can get a bank loan to build a house so I had to do as much myself as I could and wait for money to trickle in to buy materials and pay contractors for what I could not do.

The plan for the lot was to build a low energy self sufficient Efficiency House heated by a heat pump and powered by a photovolaic system. So while the building plan was being developed I prepared the site by building a garden house to house tools and my power station at the back of the lot, had a power meter column installed for a two way power meter, laid the drain pipe from the sewer manhole to where the basement wall was to be built and to the garden house at the back of the lot and laid a power line to the power station and another power line from there back to where the house was to be built.

Then my first draft plan was finished, but the neighbor to the North refused to look at or approve my plan to have a roof slanted at 25° to the South as ceiling of the first upper floor. This would have allowed the installation of twice as many PV panel as the the roof form prescribed by zoning regulations. So my architect had to go back to his drafting board and draft the biggest and highest house allowed by the zoning and building laws which would not require any neighbor's approval. This was with 2 m less length in the East/West direction but with the same North/South width. Roof inclinations of 45° above the first upper floor would have been allowed, but I chose the minimum slant of 35° to the North and South allowed. The two rooms on the 2nd upper floor resulting from this have more than twice the living space I lost on the ground and first upper floors. But the additional PV panels the obstinate neighbor installed in the Summer of 2021 do not get any sun in December and January, even though I managed to leave out half a layer of blocks in the basement and a whole layer in the first upper floor as well as the 10° lass slanted roof. As we have the same chatty PV supplier also living in our street. I am certain he was informed of these efforts to his benefit, so I have heard no more on this score, and there is nothing to disturb the serenity of looking down from the East room of the 2nd floor of the highest house far and wide in the street.

While the second plan was being drafted I dug up all the top soil and of the clay below it from and around the building area, separated all the stones and wheeled the earth to the back of the lot and formed a two meter high pile.

This freed me of another 4 kg and continued strengthening a lot of muscles besides making the varicose veins in my left leg less visible. But my arteriologist was still keen on replacing the veins with plastic tubes.

The picture shows progress as of October 2020 a sandy bottom with trenches and heat colector pipes sticking up. The West and South and West sides are covered with blue plastic sheets to keep them dry and safe.

Then the zoning regulations and dimensions of the lot dictated some rather tricky planning. The lot was only 13.56 m wide along the street side, which required a minimum of 3 meters distance to the street as well as to both neighbors on the North and South sides. Building a basement later entailed an unexpected nightmare, as building standards required an excavation slope of 45°, which would have precluded any movement along the North and South sides and did preclude putting up a crane. The street is only 6 m wide and the neighbors all have fences directly on the street (not allowed but still there) so there was no space there for building materials.

A crane would have cost about 1500 Euros per month and a permit to block half the street about 100 Euros per month. While it took all of nine months between pouring the basement floor and putting the last tile on the roof.

Chapter IV Th hard work brings the strength to carry through.

While the second set of plans were being drafted, I dug up all the top soil of mostly clay and made a nearly 2 m high pile of it along the border, and carted it to the back of the lot with a wheelbarrow, but sorted out all the stones in it and made a separate smaller pile of them in front of the garden house. For these very differently colored stones were to be embedded in the surface of what was to be dubbed "The Picasso of Driveways"This work lighten my bodyweight by 4 kg and brought more muscle power while reducing the varicose vein problem in my left leg. Although my arteriologist was still keen on replacing the veins with plastic tubes.

When the topsoil was cleared off and the hand excavation had proceeded deeper into the ground revealing some small sand pockets and, of course, more stones for my collection, the building plan could finally be submitted in December 2019.

But at the end of January 2020 the report came back from the county building permit office, that my application could not be approved, because I did not have free access to the building site. Since the 12 other parties building in in our "street" had gotten their building permits and finished building, a new office had taken charge of this area. He discovered that at least ten years earlier the town of Krostitz had refused to accept ownership of the finished street area, presumably because of some construction defects (insufficient turning area at the end of the street). This probably drove the subdividing company into insolvency. So there was no public street and no free access to the property. Insolvency procedures were prematurely closed after liquidatation of all other property, because the court ought to have at least assigned equal property rights to the respective property owners in the street to liquidate all of the company's property. The company was deleted from the public corporation registry when procedures were closed and ceased to be a legal person, but not from the land registry, where it was stillshown as owner. So the land did not belong to anyone. Hence I wrote to the land registry and declared the acquisition of the property. The response of the registry was that the right of free acquisition did not apply for registered land, which did not seem to comply with the law I remembered reading 50 years earlier in Heidelberg. So I wrote to the town administration informing them of my acquistion claim and the block for my building permit. The situation endangered their taax claims for all the houses in the street, so they decided to exercise their right to ownership of the ownerless land, with which the area paved more than a decade earlier finally became a street under public law.

So after 5 months delay I was finally granted a building permit near the End of May 2020

Chapter V. The excavation and heat collector pipes.

My plan was not approved at first because the original developer had gone into bankrupsy and the city had refused to take ownership of the street because it was so narrow and had no place at the end to turn around, so it was not a public street and I had no right of access. None of the 11 other builders had been confronted with this objection: I was the only "lucky one". But no one owned the street, so I wrote to the land registry and claimed the property, where they did not like the idea. But the city realized it was an impossible situation and quickly decided to take ownership after all, and after 5 months delay my plan was approvedin May 2020.

With the building permit in hand and the top soil cleared in May 2020, it took a month to find a company prepared to build the basement with prefabricated walls. But they did not do excavation work and suggested a specialist for this, who agreed to begin at the end of August. But when the date was nearing and he had not reported back I rented a digger and borrowed a trailer and began hauling the dirt away to a nearby repository saving whatever sand I dug up at the back of the lot and loading the clay onto the trailer.

Then I could not find anyone to make the excavation, so I rented a digger and did it myself.

After two weeks I had reached a depth of 2.9 m, where it had been mostly sand than clay, and I began leveling the bottom and informed my contractor, they could start with the basement. In the mean one of their two authorized building foremen had walked off the job. So I had to find a new contractor.

This took four months, during which I decided to dig trenches in the basement floor to lay heat collector pipes instead of having a deep thermal well dug. This proved much cheaper and over the following 6 months I managed to lay 350 m of 32 mm plastic water pipes and connect their beginnings and ends at the poit in the basement floor, where the utility room was to be.

The picture shows progress as of October 2020 a sandy bottom with the first of 6 looping trenches and the first heat colector pipe sticking up. The West and South and West sides are covered with blue plastic sheets to keep them dry and safe. It took another month of manual digging to loop the 100 meter around through the earth ramp and finally lead it back to come up again next to the other end. Six months later both ends had to be shifted 50 cm to the left to come up outside the basement floor area.

By early Summer 2021, when I had managed to get 4 more pipes into trenches and the next Summer drought was coming on, the neighbors were expressing their thankfulness that someone should build such a nice big swimming pool in their small town of less than 1000 souls.

The drought season was spent squaring out the corners of the pit and placing the 6th and last collector pipe in place at floor level around the sides of the the excavation

Chapter VI. Heat collector capacity and heat storage.

The house with 12 cm of styrodur insulation on the walls of the basement and upper floor as roof as will be described below had a calculated heat requirement of 7 kW, while the heat collector pipes have a heat yield of 1 kW per 50 meters, so a total 350 m of pipe were needed. Normally the network of collector pipes is laid out at a depth of 1.5 m in the garden, but the deeper ground below that is warmer in the Winter and constant all year round at 8 m. I could not find a report on which temperature it is constant at in this part of Saxony, so I drilled a hole 60 cm West of where the Basement floor was to end and sank a 10 cm drain pipe to a depth of 6.5 m with small hole drilled into the sides of the lowest 50 cm of the pipe to serve as an overflow from the cistern tanks and lowered a thermometer into it on a wire after the tanks were in and the pipe had been continued to the surface during the trench filling work.

The temperature at that depth was 12° C at the end of April, 13° C at the end of September, 12° C after the first cold spell in December and 11° C in the middle of February. So the normal fluctuation there is rather limited and fairly warm all year round. By running the pumps for the floor heating and the heat collector network at the same time in Summer the house can be cooled and the heat pumped into the deep ground raising the temperature there to perhaps 15° C by the end of September, so there will be even more heat to be drawn out of the ground during the heating period.

The picture shows the two batteries of collector pipe ends while I was in the process of moving them to outside the area under the basement floor.

Chapter VII. Power storage and doubled power production.

When beginning to excavate, I had also ordered two 10.2 kWh storage batteries and a 3 phase power inverter for my PV system. These arrived the end of November, 2020, and were but the battery charging units were defective and had to be replaced, which took until July 2021.

During this period 10 more PV panels and were provisionaslly mounted on the topsoil hill at the back of the lot increasing total power production to about 7000 kWh p.a. This additional power was needed after buying two used Think City E-cars in the autumn of 2019 but still yielded hardly enough power.

On 15th June, 2021, my two way power meter was outfitted with a smart meter device from discovergy.com which enabled reading consume and feed in on the three different phases as well as hourly power consumption rates as traded on the European Power Exchange.

The picture shows the progress as of March 2021: a big hole with a sandy bottom and the slope on the street side for driving the digger in and out and my tiny electric Think City in the street powered by the photovoltaic panels you see at the back of the lot. The 85° slopes on the North, South and West sides are covered with blue plastic sheet to keep them dry and safe.

30 more PV panels were ordered and paid for in October, 2021, when the price had risen a bit from the all time low the Summer before. They were not delivered until March and had to be stored in my neighbor Juergen's garage until after August, when the roof was finished, and then until he had time to help with the installation in October.

Chapter VIII. Securing the slopes.

My second contractor agreed to begin in April 2021, but had not asked my architect for the static calculations and steel layout. This took a few weeks, so my contractor started another project instead.

The steep excavation slopes began worrying my neighbor on the South side, who feared his garage might slide into my pit. So-called experts began writing pages and pages of opinion that had nothing to do with the stone-hard clay ground that was kept bone-dry all the time until 6 months after the basement floor had been laid. Nonetheless I had to spend two weeks in October 2021 preparing 16 wooden beams and countless boards to shore up the slopes and find another expert to confirm it would hold up everythng (That is everything that was not about to budge and for which I later had to bring in a heavy duty electric hammer to chisel out space for my cistern tanks).

The wooden beams were prepared in such a way as to later support a terrace roof on the south side of the house as well as serve as support of the 10 PV panels provisionally mounted on the hill behind the house, as well as supports for a car port along the north side of the house. So shoring up the sides of the excavation will not be their only use.

Enclosing both areas on the North and South sides of the house has an insulating effect too and will use the heat loss through three of the French door to heat the terrace in Winter and keep the plants there from freezing.

The picture also shows the Nissan Leaf I bought in August 2021, which is equipped with 24 kWh of V2H (vehicle to house) battery storage capacity.

Chapter IX. The basement floor is laid.

November brought a lifting of the fill order and the beginning of building work, so after covering the sandy bottom with 5 cm of lean concrete, my third contractor ordered several tons of steel that came with a truck outfitted with a crane to lift it into the excavation. Some was for later work and had to be carried to the back of the lot.The 2.5 t of steel matts, spacers and bars were bound together with wire.

It is hard to imagine how glad I felt when I saw the four cement mixers come with 25 cubic meters of concrete and make all that expensive and heavy steel disappear into the 25 cm thick concrete floor.

Actually 12 cm of extra heavy duty styrodur should have gone under the basement floor, but stocks of it had been completely depleated and delivery would have taken more than another 6 months. Instead 8 cm of polyurathane was laid on the basement floor.

Chapter X. The basement walls go up.

As said, there was no place to set up a permanent crane between the building site and the street nor enough street for one either. So no forms could be craned in to be able to pour reinforced concrete walls.

We had to fall back on good old fashioned concrete blocks and mortar masonry. So a truck outfitted with a crane drove up with several paletts of blocks and lowered them down onto the freshly hardened basement floor.

Each row of blocks had a slot in the top for laying in steel reinforcement bars to form a so-called anchor ring that can be seen in the picture. To speed the progress of the three workers, I lifted all the blocks into place on the growing walls and carried the steel from the pile in the back and laid them into the slots..

When the fifth row had been laid, a cement mixer brought a load of concrete to fill the blocks because a higher column of wet concrete might have made the bottom blocks burst. After this a second load of concrete blocks had to be ordered and craned in

But shortly after pouring the lower half of the basement walls a disagreement arose between the cantankerous foreman and head worker, Ralph, so the latter, who was the actual expert in the crew, walked off the job and work stopped.

Chapter XI. The basement ceiling is poured.

Fortunately, my son's grade school classmate's father, Kurt, had the necessary qualifications and was running a 400 unit housing project in Potsdam at the time. I had tudored his two elder boys in school in English and got them through High school, so he was happy to delegate three workers for the rest of the basement masonry of my project and get his three boys to set the forms for pouring the basement ceiling.I called in Ralph again, whose pay had been pocketed by the foreman, to supervize laying the steel for the ceiling, since then he has become an independent building contractor.

Such sturdy construction for residential buildings as well as underground telephone and electric power lines were required by German building laws following WW II, during which allied bombing cripled the infrastructure and caused many buildings to burn. So I too was convinced to minimize wood in the house especially for any structural support and in the passageways and stair areas, the only exception being the beams in the roof that are covered by very heavy tile above and largely by glasswool insulation below.

On January 7th, 2022, 24 cubic meters of concrete were poured for the ceiling. The same consideration eliminated oil and gas heating from the plans.

The neighbors had been watching the the progress of this very sturdy structure and all the steel going into it, so when the Russians attacked the Ukraine a few weeks later they were quick to congratulate me on having built such a good bomb shelter, and they knew where to go if the Russians ever invaded. In fact there is so much steel that there is no cell phone reception in the basement, but there is halfway up the basement stairs.

Chapter XII. Energy efficiency starts deep in the ground.

12 cm of styrodur insulation had to be put on outside the basement walls to be on the basement walls, so the allowable building width of 7.56 m and length into the lot of 12 m that had been reduced to 7.54 m by 11.99 m to be within bounds was further reduced to 7.3 m wide and 11.75 m respectively to assure that the insulation was also within the building limits.

Actually 4 cm of insulation would have been nearly as good for normal heating purposes, but 12 cm are definitely better and the minimum for any subsidy,

so in the end the more expensive insulation is cheaper, especially since there are fewer heating costs in the long run.

Furthermore, the energy cost crunch that followed the beginning of the Ukrainian War a month and a half after the insulation was stuck on demonstrated the wisdom of the choice rather clearly.

For the days of cheap Russian gas, 1.44 Euro/liter gasoline and 30 cents per kWh electricity from the power grid were suddenly over bringing 100 % or respectively 40 % and 60 % increases instead.

Kurt and his sons finished the insulation and stored the supports for the ceiling forms in the basement rooms by the end of January.

Chapter XIII. The battle against the trenches.

This left a trench of 0.3 m to 1.9 m wide and 3 m deep around the basement walls that had to filled as soon as possible, because regulations required putting up scaffolding for the safety of the workers buildung the walls for the upper floors.

The wooden beams and boards shoring up the embankment were pulled up in a day and real work began.

I calculated a volume of 150 cubic meters for this after deducting the 7500 liters for the cistern tanks to be placed in the west trench in the back.

But the paths along the North and South sides were only 2 m wide and the embankments were a steep 85°, so no heavy machine could possibly move along these paths. The trenches had to be filled with one 80 l wheelbarrow load at a time. That adds up to 1800 loads: quite a bit more than one day's work.

There were only about 60 cubic meters of topsoil, sand and sandy clay piled in the back. The topsoil was saved till last, while sand and clay kept me busy the first half of February.

Then I had several 8 cubic meter loads of recycled concrete and later sand delivered and dumped on the street side in front of the house and had to be shoveled into the wheelbarrow and pushed in the other direction along the narrow path. This took all of March and April to be shoveled into the wheelbarrow and dumped into the trench, and May saw me putting the cistern tanks in place laying the pipes to the points where the eaves troughs were to bring the rain water down from the roof, which was, of course, still only on the building plans and in my imagination.

Along the South trench a manhole had to be built to allow access to all the heat collector pipes. Originally I had planned to have them come up through the basement floor and be joined in the utility room, but there were misgivings about water seeping in at such a depth with 12 pipes coming up, so I decided to run only two pipes out of the basement wall 1.25 m higher where there would be less pressure and where access was possible without taking up the basement floor.

The ceramic hollow blocks shown in the picture were the standard insulation back in the sixties, in the seventies there came an insulating of stucco, but in the eighties 2.5 cm of Styropor became standard and was succeeded by ever thicker styropor.

Chapter XIV. 7500 liters of rainwater.

The three 2500 liter 2 m high cistern tanks were delivered on 18th March and each was bound to a wheel barrow and wheeled along the South path to the back of the lot, where I had used Kurt's heavyduty Hilti to chisel away the stone hard clay trench wall on the West side to make room. This clay was shoveled around the corners to the North and South trenches as fill material.Sand was filled into the close quarters around them to make sure it settled in quickly and could slip in around the complicated pipe system joining them, conducting rainwater to them and leading the overflow to fall pipe between them.

Chapter XV. The basement stairs.

There are companies that make reinforced concrete stairways, but you need a crane to lift them off a truck and put them in place. MaxiKraft had a dozen big crane truck on a lot just 500 m away from my building site and could have come over every time I needed to crane something in at 350 Euros an hour, but that would have blocked the street, for which a permit from the city is needed that would have taken time and above all no small amount of money.

Kurt had a Polish worker with experience in making forms for stairways who worked three days on making the form.

Kurt's masons were able to pour the basement stairs in April. A lot of steel went into them too.

In the end it proved cheaper to do it this way.

Chapter XVI. The ground floor walls go up.

At the beginning of April while the filling work was nearing an end, Kurt put his masons to work on the lower part of the ground floor walls.

The picture shows the rain water pipe system weaving its way between the tank manhole columns and the basement window wells. It also shows the steel reinforcement for the concrete column between two French doors that were already on the street with all the other windows awaiting the time for their installation, because the Polish producer delivered them four months too early. The permit to store them there cost 120 Euros, which was cheaper than refusing to accept them and have them driven to the import company in Dresden, unloaded there, stored and reloaded and transported back again.

However, the early payment in November 2021 saved 25 % of what they would have cost, if ordered and paid 6 months later.

The steel reinforcement bars pointed skywards are statically necessary here because two French doors will be on each side of them with otherwise little support for the concrete ceiling to come.

Two equally wide windows are to come directly above the French doors, so the steel reinforcement continues through the ground floor ceiling in one line to the first floor ceiling and from there to the roof.

If I had thought about it carefully early on, I would have placed the French doors about 1.2 m further north in the wall and extended this concrete pillar up through roof

so that it would have been a sturdy anchorage for a micro wind turbine mast at the top of the north side of the roof where it would have cast no shadow on the photovoltaic panels on the south side of the roof.

But zoning regulations require a building permit in an exclusively residential area for micro wind turbines.

And the building authorities want zero complaints about such things.

However, photovoltaic power is only plentiful from 1st March till 31st October, while heatpumps need the most power exactly when it is not coming from the sun and is most expensive from the public power grid. So this has to be changed to minimize irregular power loads for the public power grid and the risk of power outages.

Chapter XVII. Making space for 7 French doors.

Although large window areas entail some heat loss in Winter, I want to have a lot of light for big plants. The doors and windows on the street awaiting installation were, however, triple pane sealed windows filled with argon, and the outer pane was a fused glass and plastic meeting the standard required for an efficiency house, and hence a subsidzed investment.

The picture shows the 3 m concrete beams over one such window extending beyond the South wall, where it is to afford support for the terrace roof.

Chapter XVIII. .

On 12th April Kurt began bringing up the form supports from the basement for the ground floor ceiling. And I brought up many of them myself.

The picture shows them in the East room through the 2 m wide and 2.2 m high hole where one of the 7 French doors was to be installed 2 months later.

Chapter XIX. The groundfloor ceiling is poured.

On 9th May, 2022, the steel matts and bars had been placed on the forms for the ground floor ceiling and four cement mixers came one after the other and 24 cubic meters of concrete were pumped up.

I kept busy with walls in the middle section of the basement to separate and area for a toilet and shower from the utility room and a wall to close off the area under the stairs as a cool room.

The picture shows Kurt and his boys pouring the concrete.

Chapter XX. The first floor walls go up.

After the ceiling had hardened another load of cermaic blocks was craned onto it

Kurt began putting up the Scaffolding near the end of May, and his Czech masons began their work on the walls.

I cannot say it was upstairs, because the form for the stair was yet to be built, so there were no stair going up there just a ladder

Chapter XXI. The floor heating in the basement.

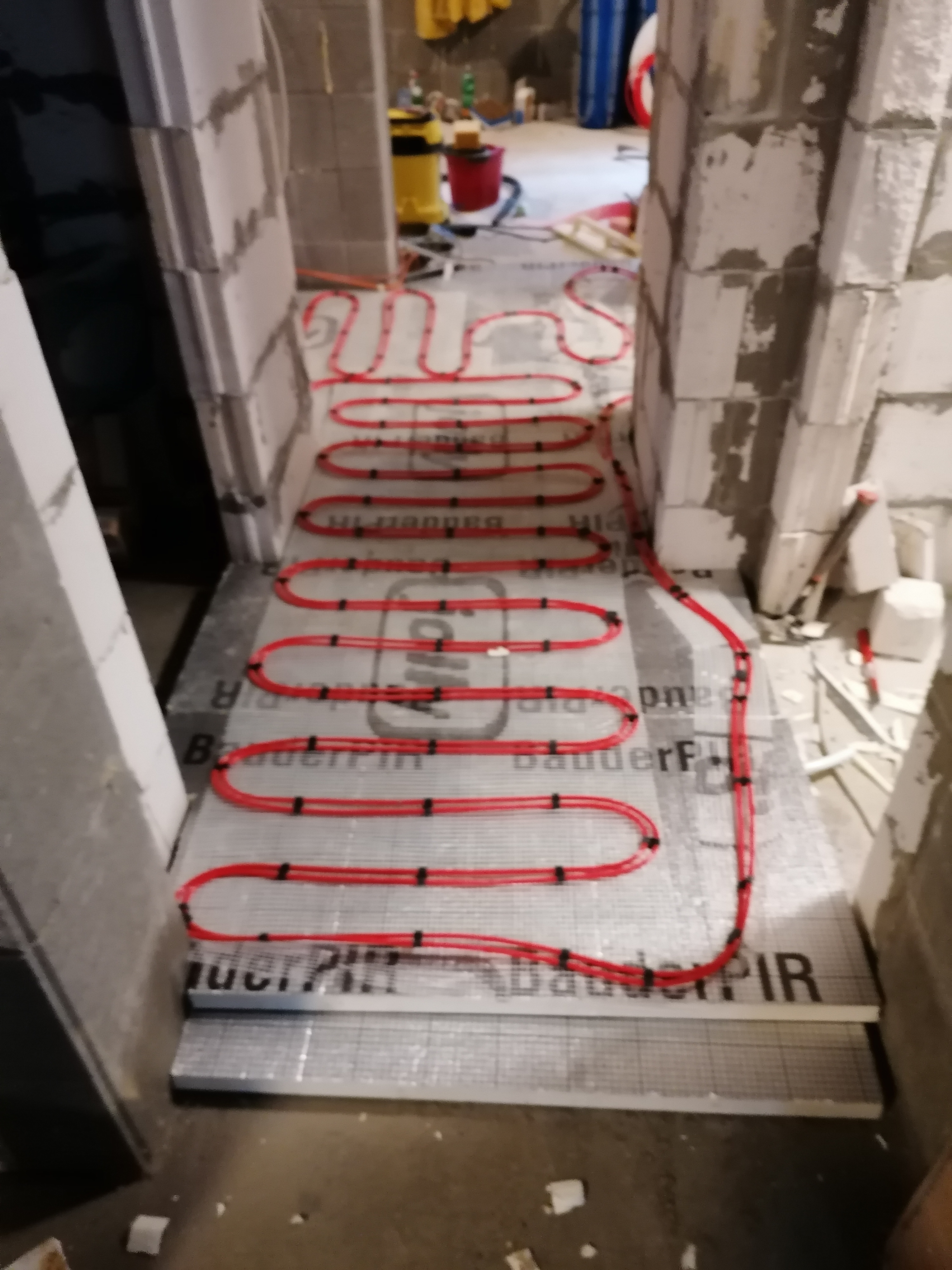

After putting up most of the wall in the basement middle section, I laid out the 8 cm of polyurathane in the passageway and toilet and began laying down the floor heating matts

The picture was taken from the West basement room, the door to the utility room is on the right, the door to the cool room is on left, the passage to the stairs behind that and the East room at the end.

When the basement walls were going up I had put a plastic pipe in the blocks along this passageway with three cable in going up to where the ground floor circuit breaker box was to be installed. Later when the forms for the basement ceiling were in place and the steel matts and bars were being laid, I put another plastic pipe with the cable from the power station in the garden house along the top of this wall to come up next to the other cables, still other cables were laid between the points above where the light switches were to set to the points in the ceiling where I wanted lights. So when Slawek, my brother-in-law, came to help at the end on May, it was quick work putting in the circuit breaker box and outlets and switches in the basement.

Chapter XXII. The walls get higher.

Kurt's masons began putting up the first floor walls in June.

Chapter XXIII. The battle of the bulge.

The beginning of June found me 7 kg lighter than I was in January and my physician entirely pleased with my blood sugar values and ECG.

Sustained filling, pushing and dumping a full wheelbarrow up to 20 times per day definitely burns a lot of calories. But it is a work load that no couch potatoe should try: it was something I had been working up to for 6 years and had been having quarterly check-ups and blood tests at the doctor's.

By 8th June the first floor walls were up, the ceiling forms and reinforcement steel in place. So it was time for me to go up and put the wires in for the ceiling lights.

The selfie taken from where the floor of the East attic room was soon to be poured; maybe not a handsome man anymore but certainly feeling very healthy. And me and my building plans were finally getting up in the world.

Chapter XXIV. Preparing for the roof.

The East gieble is almost finished. the form for the reinforced concrete suppoort still has to be made.

Chapter XXV. Lifting up the beams for the roof.

The two main wooden beams to go in from East to West are being craned up, that will soon hold up the rafters parrallel to the oblique walls that have been topped off with reinforced concrete for better distribution of the weight of the roof.

Chapter XXVI. Saving heat loss and penetration in the roof.

The wooden rafters were first covered by a water impermeable sheet that lets water vapor through. Then came a 10 cm thick layer of polyurethane aluminum sandwich panels (space technology)

to keep the heat in in the Winter and out in the Summer. Then the wood above the beams needed to hold the sandwich layer in place and to space this from the horizontal wood layer for the ceramic tile to hook onto.

The tile are rather heavy with curved edges to keep the wind from lifting them off and glazed to keep any moisture out, so that the rain washes them clean and shiny again and again for decades. Of course, in dry spells the fine dust from the planes flying over and vehicles driving along

the nearby highway and motorway can dim that shiny look till the rain comes again.

Inside came another 15 cm of mineral glass wool between the rafters, a watervapor impermeable plastic foil and plaster board to hold it up.

I insulated a house roof that had been built in 1972 with 10 cm of mineral glass wool in 1977 with a thin aluminum sheet to tack in onto the rafters, and thought I was making great savings. That did reduce the heating bills about 20 %: great work for way back then, when exterior styropor was not used on the facades and the honeycombed bricks (like I used for the new walls) had not come onto the market yet.

The following Winter, the temperature in the house never fell below 10° C even without a heating system, although December and January brought many a -5° C night and there was such a large window area. So the insulation really does what it is supposed to do.

Chapter XXVII. Floor heating for the West basement room.

While Kurt's masons were busy putting up the walls on the second upper floor I was down in the basement laying the matts for the floor heating in the West room and pouring the special thin layer Estrich.

Chapter XXVIII. A house roof is held up by wood.

European cities and towns have long had houses built close together, so a roof has to be topped off with ceramic tile to keep any cinders coming down from setting the house on fire.

YES, tile are a must, because shingles with bitumen in them are a fire hazard and not allowed on the rooves of dwelling houses in Germany.

But tile rooves are very heavy and have to be held up by sturdy beams and rafters.

Chapter XXIX. An efficiency house is topped off in the roof.

An efficiency house is topped off at the the roof with 15 cm of mineral glass wool and sandwich panels of 10 cm of polyurathane sandwiched by two aluminum sheets on top.

But before putting those on you want to keep the water out of the space where the wooden beams and rafters are, if it should somehow get by the tile on top.

And you want to let any water vapor out, if it should ever possibly get down to the wooden rafters.

So sheets of a special synthetic cloth are spanned across the rafters. Then any water from above rolls off, but any water vapor from below is let out.

Chapter XXX. Have a polyurethane and alu sandwich? Pure space tech with an out-of-this-world zest.

The 10 cm thick polyurathane sandwich is straight out of space technology for strong light surfaces that reflect heat and insulate well.

Chapter XXXI. Under the roof.

Inside the mineral glass wool is squeezed in between the rafters and then covered by plasterboard.

The sight of the rafters and supporting beam lend a very cozy look to the attic rooms that offer about 45 square meters of living space guaranteed to be cool in Summer and warm in Winter.

Chapter XXXII. The roof was also made for changing the sun's energy into electric power and collecting rain water.

Rooves have always been made to keep the folks living under them dry but mine was also made for changing the sun's energy to electric power and collecting rain water for hot dry sunny days.

Each of the two rows of 12 photovoltaic panels generates up to about 5000 Watts. In addition they keep the tile under them from getting hot on a sunny day.

Chapter XXXIII. The three pane and argon filled windows.

First after finishing the roof the windows that had been standing in the way on the street for over 6 months and were finally installed in the third week of July.

They had been blocking access on the North side and made it inconvenient to get in that way.

Chapter XXXIV. 12 cm of styrodur on the fassade.

Then came more 12 cm styrodur on the facade as the next step towards and efficiency house. But the disastrous highrise apartment building in London that had burned with such insulation resulted in the requirment of a row of mineral glass wool blocks between floors for fire protection.

Chapter XXXV. Heat exchanging ventilators.

Such efficiency house windows prevent any air from coming in when closed. So efficiency experts came up with an idea to keep people from opening the windows in winter:

A ventilator that alternately blows stale air out through a honeycombed ceramic pipe that absorbs the heat and then later pulls the fresh cool air from outside in through the same ceramic pipe that warms the incoming air.

It actually works, fresh air fanatics are much seldomer caught tearing open the windows.

The picture shows the machine for boring a neat hole for such a ventilator. In all four such ventilators are installed in each of the 4 kitchen areas.

When the flooring heating pipes are used to cool the house on hot summer days, the stale air cools the ceramic pipe on the way out, while the ceramic pipe cools the fresh hot air on the way in.

Chapter XXXVI. Plaster for walls and ceilings.

Doing the roof, eavestroughs and windows swallowed up the bank loan and other income and left a big hole in finances accompanied by ebb tide in income.

But a lot of rain in August filled the Cisterntanks rather quickly. So only I continued working at all and on the water system.

The plaster on the walls and ceilings is the product of Abdullah's masterful hands.

Chapter XXXVII. Tile for the basement passageway.

While Abdullah was plastering, I finished the basement walls and water pipes.

When he finished plastering the basement passageway I laid the tile with a knotty pine pattern there.

Chapter XXXVIII. Stucco and reinforcement matts on the outside insulation.

Two layers of stucco facade mortar are spread onto to the facade insulation with plastic matting inbetween to protect the insulation from being dented or damaged. This was finished 22nd February, 2023 by Abdullah and his crew, whom I had hired in December for the plaster work.

The silicon granulat top layer of the facad had to be done in warmer drier weather, so that had to be waited for.

Chapter XXXIX. Floorheating and concrete subfloor.

The concrete for the subfloor was poured the 21st of March. I had been under pressure to get the insulation and floor heating pipes down and the last of it was completed at 10 AM a full 2 hours after the contractor arrived with his mixer and concrete pump and just before the load of sand for it came. The delay starting work on the heating pipes had come from other jobs like putting network and antenna cables through to all the rooms, moving materials, tools and furnishings to the attic, stairs basement, and a room to be done later, beginning the enclosure of the shaft for the ascending and descending heating pipes and cables and a general clean-up, which had taken about ten days.

By 4 PM the men left a slick flat floor everywhere, and all 400 m of the heating pipes I had spent about 15 days laying were gone and never to be seen again.

The picture shows the front door and vestibule, as well as the stairwell going up on the right with a hint of all the materials stored all the way up.

Chapter XL. Primer on the facade insulation.

The primer has been put on the the lower stucco layers but we are still waiting for a few successive days to put on the granular silicon layer.

Chapter XLI. Waiting for the scaffolding to come down.

A layer of stucco was put on the primed insulation and covered with the plastic reinforcement web sheeting then covered by another layer of stucco.

Finally white silicon granulate was put on top to seal it.

At last the ventilator shafts on the north side could be cut to length, the lightning rods addded on the east side, and four photovoltaic mounted vertically on the south wall. The power production in December and January had proven to be very weak, so they will help on the days when the rises only 13° above the southern horizon, if the sky is clear, of course.

The floor insulation has been put down in al ground floor and first floor rooms, and the flor heating pipes laid out and concreted over. But before laying the tile over them the heat pump has to be installed and heat the floor up once. So that is another 3 week hold up.

Chapter XLII. Now the choice between Landscaping and inside work.

The need to be able to park on the lot, get rid of left over materials and get some potted trees and grape vines into ground as soon as possible dictate one choice: Getting the topsoil needed to bring the front and back sides of the garden up to the level to step out of the French doors is needed most, while having a container of about 5 cubic meters brought also brings a container for carrying away the unsightly junk lying around.

But first the driveway and terrace area on the south side has to be covered with pavement stones so the soil can be wheeled to the back, then a 60 cm high wall around the front garden area has to be put up to hold the top soil in on the street side. The the driveway on the north side has to be paved.

Jürgen managed to install a third inverter and mount 4 PV panels on the south wall before the scaffolding was taken down, so with the days getting long and the sun higher every day power production was increased enormously compared with the months before eliminating the need to draw power from the public grid and increasing the power fed into the grid to as much as 52 kWh per day in the latter half of April despite consuming as much as 4 kW of power to heat the house and 2 kW to charge the car.

Chapter XLIII. Clearing and paving the way around the house.

After provisionally paving the south terrace to the middle of the house work was stopped by a palette of mortar bags that had been there for a year. So I had to start working the other way around the house making a wall to hold up the 50 cm elevation on the east side and paving the parking area along the street and the drive way on the north side with a mixture of the mortar with ready mix concrete and topped of with the thousands of stone I had dug up and set aside for this before beginning basement construction.

When work on the wall had progressed far enough to retain the top soil for the east lawn, two loads of top soil were ordered totally 9 cubic meters, while the container for the first load was left next to the pile of top soil on the street to be filled with the junk left over from building. This made made five feverish days of work shoveling the top soil off the street to behind the retainer wall and collecting about 7 cubic meters of junk to fill the container by the following Tuesday, when the container was to be taken away and the second load of top soil was to be brought.

This brought my weight down to what it had been a year earlier. While mixing the concrete and mortar bags to pave the driveway up to the house door got it down to a 35 year low of 89 kg.

The picture shows the pavement sloped up to the house door level as a barriorfree entrance and my e-car finally parked off the street, while taking a charge of sun energy straight from the roof top above.

The gridfeed rose to 73 kWh on one day by the middle of May, ten times as much as needed for an average 3 person household.

In April the hope to get professional help in the utility room for the connection of a pressure regulation, filter and purification of the cistern water supply fell through, as did other other attempts in May. But by the end of May I had all the equipment needed and had tiled the floor and walls there, where it was all to be mounted in more DIY work.

The same story played out for the heatpump no plumber registered for subsidy certification wanted to connect a heatpump with the heat collector and floor heating pipes I had laid. But buying an imported HP proved to be only a quarter as expensive as one made in Germany, so in DIY the whole system costs about 10 % of the profi price tag. As the delivery was not possible until the middle of July, when most of the other urgent jobs would be finished or had to be postponed until after the HP installation, this proved to be no problem for scheduling.

Laying the tile flooring before running the heating system up to expansion temperature is what had to be postponed. To move in in June required laying vynil flooring provisionally. This allows me to save this expensive job for my DIY planning until I feel like doing it, which is not likely to be anytime in 2023. The tile will be stored along the north wall of the house for at least 6 months.

June 2023 ended with all walls except the stairwell and attic painted, the vinyl flooring down in the three ground floor rooms, as well as the the doors in there, one bathroom functional and nearly tile and the the cabinets half assembled in one kitchen. The tracks for hanging the drapes and curtains were also up in the three ground floor rooms, while the velvet drapes were already being sewn. But the cash was getting thin and the delivery of the heat pump around the middle of July would swallow the funds expected to arrive before then. This left only the pumps for the floor heating and the heat collector sytem to be bought and installed to make the heating system functional and get the subsidy.

The drought from the middle of May until the last week of June and the need to water the new trees and bushes emptied the cistern, but a hose passed over the fence to the neighbor filled it again and kept our water system running.

Two particle filters, and a UV purifier were in the system and an active carbon filter acquired, so water quality was assured.

Chapter XLIV. The heart of civilization is a dust free room behind velvet curtains.

A room with 3 French doors is great for looking out over the garden during the day but needs a 12 m width of dark red drapes to help you avoid that aquarium feeling after dark when the neighbor's tom-cat is on the prowl.

The drapes also increase the insulation quality of the house design by keeping a temperature difference between the air in the middle of the room and the air temperature next to the outside walls.

The end of July saw one bathroom finished, a second nearly finished.

After two years of preparation and three years of construction work my weight had dropped from 104 kg in March 2018 to 88 kg in August 2023. So my fitness program was keeping pace with the progress of work

Chapter XLV. Between the two blue velvet drapes in the study the rubber tree thrives and blossoms freed from dust.

After finishing all 3 ground floor rooms and freeing them of dust I was able to start bringing up the dusty furniture dust it off and begin adapting and refurbishing the self made items.

Between the blue velvet curtains the rubber tree, that had grown to over 2m height during the 7 years after being rescued from the trash that another tenant left behind in the Lortzing Street house and had had to put up with all the dust over a cold Winter in the new house, suddenly began to thrive and blossom strange tropical red flowers. Perhaps being in sight of me, my computer and refurbished and reshaped desk and having a whole French door for herself was exciting, for these blossoms are far more beautiful than anything she had sprouted out before.

While waiting for more money I continued moving up furniture from the basement, dusting it off, refurbishing it and adapting things for the rooms. But a house with so much glass in the exterior walls offer little wall space for wardrobes, china cabinets, bookshelves and the likes of that, so I decided to make the larger furniture pieces easily moveable and keep the use of the house as flexible as possible. Putting wheels under our bedroom wardrobe and under the secretary I made for Bogda 11 years before as well as painting their backsides white to function as a partition across the west or middle rooms upstairs as well as more wheels under some two sided bookshelves yields an impressive set of partition elements for keeping a large art of ur househld goods. And all can be moved around anytime we want in a few minutes.

Chapter XLVI. The superficiality of velvet drapes, finished floors and furnishings gets a chilly awakening come Autumn without a heating system.

With the ground and first floor room dustfree, finished and in a liveable state, and Autumn rapidly approaching, towards the end of August it was high time to tend to the heatingh system.

The heat pump that had arrived shortly after the drapes in July and had found a provisional place in my office resting on a trolley before the threshold to the basement stairs being pushed back and forth between there and a place before my desk. This did not seem to bother the rubber tree, as the HP was always on the dark side of my desk not getting anywhere near her light transmitting French doors.

But a heat pump had no place in a study, of course, and certainly no need for French doors, although its descent into the dark depths of the basement had to wait until the basement stairs had been cleared of the building materials stored there and a support was made for the block and tackle to lift it down the stairs.

It took me till August to get around to building a frame with a strong hook to be leaned between the steps and the stairwell ceiling with my block and tackle hung from the hook and the block hooked onto the network of ropes around the heat pump, which lowered it down the stairs, a few steps at a time with the frame following a few steps at a time with the trolley at the bottom ready to give the heat pump its final ride into the utility room. There it will live out its days happily pumping the heat out of the deep ground in the Winter to spend warmth for us, the rubber tree and many another tropical plant basking in what little weak December sun there may behind the other 6 2,2 X 2m French doors and the 7 large 2 X 2 m first floor windows.

And in the horrid heat of Summer the Heat pump can pump the sweltering heat into the deep ground so there is more heat down there to pump back up again in Winter.

Another sum was finally credited on 20th August and went mostly into finally paying Roman and Jürgen for their work in July or respectively in May,

while the rest went for fittings for the heating system and a satellite antenna.

So I could turn to connecting the two batteries of 6 heat collector pipes in the manhole ouside the south basement wall with two pipes coming out of the utility room wall

after slipping in two more T fittings with blind endings, in case I discover that additional heat collection loops are needed to get enough heat out of the ground.

(I certinly do not relish the task of digging 2 m deep trenches for that, but buying a 14 kW heat pump instead of only 8 kW only cost a few hundred Euros more,

and the figure of 7 kW heat need for the house did not include heat for the basement and 2nd upper floor nor for heating an enclosed terrace.)

Hence a plan B is in place here too, if more heat collection is needed.

In the manhole to the heat collector system, there is still the job of insulating the pipes from the basement wall to where they disappear into the ground at a depth of nearly 3 m. But until the heating system is working properly easy access to all the pipes might be necessary.

Chapter XLVII. The heat distribution.

Then came the connection of both groups of four pipes to and from each of the four floors for distributing hot water to the four floors and returning the cooled water from each of floor to the utility room, where there are two steps of enlargement from 20 mm to a single 1" pipe as well as another pair of pipes to and from the conservatory terrace, which now await only the pump to connect them to the heat pump awaiting its integration into the system.

Then when insulating the utility room floor before tiling it in May I had extended the pipe loop under the passageway to the cool room under the basement stairs to be connected with the heat collector system by the two pipes coming up from the floor in the picture to where the collector pipes come out of the Basement wall and lead through 1" pipe extensions to the pump for that system and return intake on the heat pump.

Here too the need for some insulation is obvious, or the utility room will get warm, while the house cools to a temperature that only a polar bear likes.

Another sum was credited sthe sewcond week of October and was enough to cover the two water pumps and whatever electrical equipment is needed to power and control the system.

Until then I had to busy myself with paving the rest of the driveway on the north side of the house, so my wife can also park her car there.

Chapter XLVIII. The home network.

In the spring of 2023 I put in 2 network cables from the middle ground floor room to each of the 11 other rooms of the house. In August 16 plugs were clamped onto the ends of them and plugged into the switch that had been bought in February.

The network cable from the power station in the garden house was had been laid to the basement-wall-to-be 3 years before this and in Dec. 2021 put into a pipe from there to my "office-to-be" in this middle room of the ground before the concrete for the ground floor was poured in Jan. 2022.

So in August nearly half of terminals and plugs needed complete the whole network system were finished.

Chapter XLIX. The bathroom cabinet.

In 2020 I had bought two bathroom cabinets two flowthrough instant water heaters. The latter were found in basement storage rather quickly when needed, but the former got lost amongst many boxes of books and other household goods. However, as more and more furniture found its way back into the civilized world, they were finally found and brought up, mounted and the wires for the LED light were connected too, flooding all in indirect light. The two side mirror doors, that can be set to see the back of your head, let me know that the back of my head had become a little balder in the two years since I had last been able to see it.

Otherwise the cabinet lent the bathroom a rather splendid improvement.

The sink had been brought with us from the flat where I had installed it in 2012 but needed a wider board than had supported it before.

the second cabinet like it will be installed in the bathroom above it, but a glass sink with whit opaque bottom side will be installed with a dark oak-patterned board supporting it. The same beige Malta patterned tile will be laid there, but the same beige colored bathtub is 10 cm shorter there than here.

Chapter L. The 2023/24 Winter is on the way.

Paying for the heat pump in June brought ebb tide into the finances for the rest of the Summer. So I concentrated on bringing up the furniture the basement room where the floor heating still had to be laid, refurbishing and adapting it for the new rooms. Then the floor heating still had to be laid in two of the 2nd floor rooms and concreted over, which was done the last week of September.

October brought the funds for the two water pumps and other fittings for the heat collector and floor heating systems.

By the 15th the last connections were made in the utility room and the basement room was cleared for laying the floor heating in the last of 10 rooms in the house (not counting the 6 baths, utility room and the cool room under the basement stairs, of course). The only things left to do after finishing there were an air pressure check for leaks, the electrical connection and electronic controls, whereby the latter are only necessary for control freaks, because the heat pump has a mind of its own, at least according to poorly translated manuals.

By the way, the picture does not show a snake pit. Here the utility room was photographed diagonally from the the top of the door frame, and the rotated 90° counter clockwise, so up is to the left, down to the right, while East is down and West is up.

For those, who are not seasick yet: the top of the heat pump has been taken off to get a good look at its guts. The compressor of this black beast is just out of sight on the upper right. The heat exchanger is the coiled double pipe that you can see through down to the bolts holding the support on the bottom The inlet from the heat collector system is seen at the back of the HP on the bottom, and its outlet above that at the back, The inlet from the floor heating system and the outlet are above that in the picture but covered by the exchange coil for the water heating coil above the collector exchange coil, while the two black pipes with blue heads coming in through the basement wall from the manhole shaft outside where they were joined to two batteries of 6 pipes each leading down to or respectfully coming up from a depth of 3 to 4.5 meters under ground, where the temperature still measured 13° C in mid October week despite colder night temperatures.

That may be too cold for the comfort of many, but the heat pump is designed to extract enough heat from even colder ground. to heat a water boiler up to 85° C. And I only need to keep my floors over 22° C.

There are 5 pairs of 20 mm white pipes coming into the utility roomm on the left in a series of two enlargement up to 1" and fittings for filling, temperature measurement and air-bleeding before being joined to the water pump, the white expansion tank and then the heat pump.

As soon as everything works properly pieces of insulation left over from other jobs will be cut to shape and stuck in with PU foam with removeable lids of the same and all wil be tiled over.

The beginning of this insulation can be seen between the two white pipes on the lower left coming up from the floor. They are joined with the heat collector system, because they run under the basement floor insulation across the passageway to the cool room opposite the utility room. There they were supposed to keep the temperature under 8° C, but only a normal door and 20 mm of styropor insulation on the walls and ceiling only 13° C or a difference of 5° compared with the other basement rooms was achieved.

Chapter LI. Two months into Winter show what a heat pump can do

After all pipes and water pumps for floor heating and heat collector systems were in place and connected to the heat pump by the last week of October some leaks in the floor heating showed up that had not showed up in the initial air pressure tests, Tracking these down, getting at and stopping them took three weeks. On the 14th Nov. both systems could be filled and the pumps plugged in. The water had to be circulated for a day to get the air out and the water flow rate up th 1.0 or respectively 1.2 cubic meters per hour. Then the heat pump was plugged in and diagnosed Error 1 on the control display, so consulting the crudely translated operating manual, I was able to learn the 5 wires in the 380 V 3 phase plug were poled in the reverse order. By switching two of these the right order was attained and the control panel only complained that the non existant hot water boiler was not filled. It took the HP about a minute to evaluate the data from its sensors and decide to switch on the compressor, after which the thermometer for the water going into heat collector pipe gradually dropped from 15° C to 0° C, while the thermometer for the water going into the floor heating gradually rose from 18° C to 45° C. The next morning the three upper floors were a comfy 20° to 22° C despite the overnight outside temperature having dropped below 8° C. Our www.discovergy.com power meter reading revealed that the HP had consumed about 800 W on each of the three power phases.

Since the recommended flow in the heat collector system was 1.9 cubic meters per hour and 2.4 cubicmeters per hour for the floor heating, a stronger pump was bought for the floor heating and the one for the floor heating moved to the heat collector system and other measures taken to increase the flow rate in the heating system. After another month the flow was up to 1.8 m3 in the collector system with water being sent into the ground at + 5° C and returning at over 10° C, while the flow in the floor heating was increased to 1.5 m3.

After commisioning the HP again, it became evident that air in the ground floor and 1st floor heating systems was blocking the flow through them and that installing automatic air bleeders in the basement and second branches was not enough and that these branches should have been individually filled with water. Howerver, loosening a fitting on each of these floors gradually helped the flow, but it took 3 weeks before the heat at the floor distribution points was distinctly noticeable.

The temperature sensor for the floor heating was tucked under the insulation before the water pump and the HP configured to heat to 39° C. However a thermometer is inside a fitting after the water pump reads 55° C when the HP shuts off after heating for about 6 minutes.

In the course of the remaining Winter I managed to discover what was not explained in the operation manuals: Access to the settings is only possible during the start up phase after turning on the electric power again. So I was able to successively lower the switch off temperature to a nominal 27° C or actual 36° C.

When the sensor reading drops to 33° C after about 20 Minutes, the next heating phase begins. This brings about 48 to 60 heating cycles per day (depending on the outside temperature) of about 0,3 kWh power consumption per cycle. The ratio of heat delivered to power consumption is about 4.4, so the heat getting into the floor heating is about 64 kWh to 80 kWh per day from 14 kWh to 18 kWh power consumption. Our power supplier, aWATTar.com delivers power at hourly rates currently varying between 0.0003 € and 0.09 € per kWh plus grid service and other fees amount to about 0.08 € per kWh, but often much more. So on a gray day when the PV system is not producing, the heat costs from about 10 € per gray day to as much as 50 €.

The e-car does not charge itself in winter either and can easily consume another 8 to 10 kWh per day.

Chapter LII. Photovoltaic inadaquacy.

With 25 or more gray days per month from 1st Nov. till 28th Feb. it can get rather expensive and cause quite a fluctuation in the power need from the public power grid, not to mention the unwanted CO₂ and fine dust exhaust. If we managed to get 10 million households converted to PV power production and heat pumps by 2026, it will cause a 500 million kWh saisonal fluctuation in power consumption and require gas powered generators to be held in reserve to compensate for this with additional costs to be covered by the Summer consumers.

Above all there is no way of attaining self sufficiency without micro windpower units or some other cheap additional power source, which a focile fuel powered generator with all the fuel taxes is not.

But three micro wind turbines on masts at least 10 m above street level with a rotor diameter of 1.5 m can produce up to 1.5 kW of power each

and together average about 0,8 kW to 1.5 kW or about 20 to 36 kWh per day, which can compensate the slump in winter PV power production genau zu der Zeit des höchsten Verbrauchs.

This would guarantee a regular power surplus and avoid seasonal burdening of the public power grid with gray day consumption up to 36 kWh per day after covering HP, E-car and normal household consumption.

The need to mount micro windturbines at a height of 10 m or more i.e. above the air turbulence from trees and other rooves to achieve self sufficiency in renewable energy makes it clear,

that houses with only a ground floor require much more expensive masts tha will make the landscape a bit unsightly, i.e. they were not built for this millenium but the last,

although the need for renewable energy to prevent climate change was already being propagated 30 years ago and building regulations should have been changed then and not sometime in the future.

Builders have been wasting money for decades because building regulations have not required them to build the way the need for renewable energy require.

A relatively steep roof of 40° to 50° is best for the winter sun, and at least a 3 story house is high enough to require a relatively short and cheap mast for a wind turbine.

Chapter LIII. Heat pump performance.

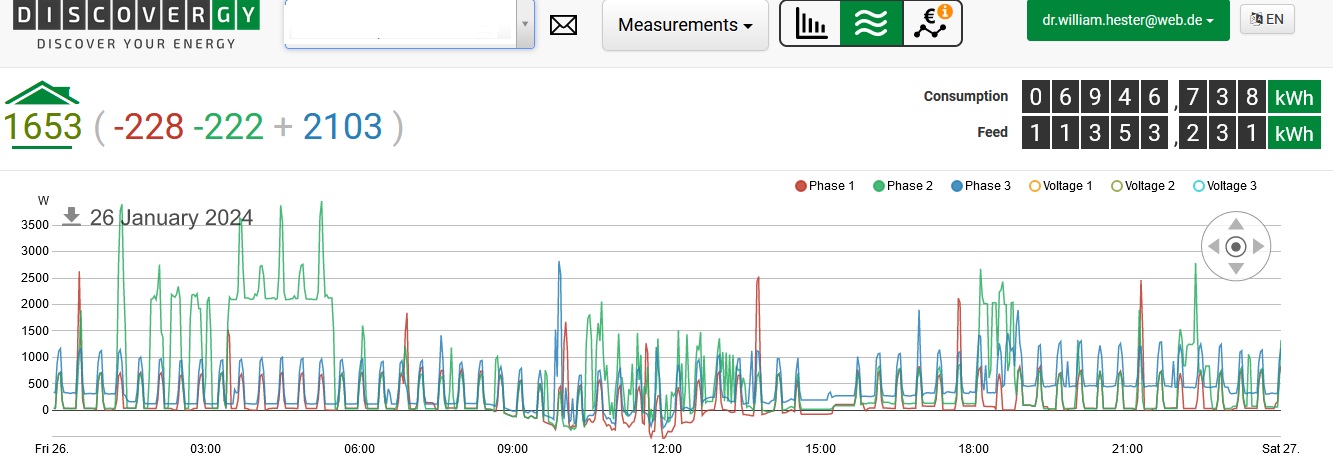

To estiimate the heat pummp performance using the consumption data of 27th January, 2024

the other consumption devices have to be eliminate from conideration:

The cable for charging the e-car was plugged into phase 2 and the charging time set for between 0:10 h and 05:30 h,

which is shown by the greene line in the graph by 2,1 kW of its height during charging period, roughly 5 kWh.

At 10 h the computer was switched on on phase 3, which is 200 W of the blue line after that over the entire width until 18 h.

After that the electric heater was also switched on phase at a steady 1000 W.

The kitchen devices are also seen on phase 2 at about 10, 13 und 18:30 h.

Presumably an inverter causes periodic consumption spikes on phase 1 of 1800 W at about 0:30, 3:30, 6:50, 10:00,, 13:40, 17:40, 21:15.

The remaining consumtion peaks of 800 W each on all three phasess are the HP.

In order to estimate these more exactly, graph was stretched over thewidth of all three monitors with yeilding half hourly time intervals,

to measure the time spacing and consumtion peak widths or duration in mm on the screen.

There are about 62 such heating periods per day of about 0.240 kWh or 14,9 kWh per day for all 62.

At an outside temperature of 1° C low and 8° C high the house could be kept at an inside temperature of 19,5° to 22° C

with average 0,621 kWh per hour. The relation between heat delivery into the heating system and power

consumtion is generally 4,4,

which allows an estimate of heat loss to Outside of 2,73 kWh per hour for this outside temperature range.

For 10° colder outsid temperature loss is, of course, higher with a tlme lag for thew changng heat gradient over about a day for all such variations.

This corresponds roughly what my energy advisor calculated for consumption.

Chapter LIV. The back parking area.

In March 2024 the grid stones were taken from the driveway extension int the back yard and a load of black soil loaded into a trailor at a neighbor's house at the end of our street and pulled over to fill the last holes in front and level up this parking area in the back yard. Then the grid stones were laid out again and the other gridstone on the south terrace are were moved over here to extend farther into the back yard.

Parallel to this work the concrete paving stone were pulled up from the south terrace and stacked up in the SW corner of the lot

and 12 square metters of new one bought and stacked up at the back of the driveway for later use paving the south terrace after the next major project.

This may not look like much but in all about 20 tons of material had to be moved by hand, shoveled and/or carted by wheelbarrow.

Chapter LV. The extension of the heat collector pipe system.

As explained above, an analysis of the heat pump activity revealed that water was moving throuh the heat collector pipes too fast for its temperature to be raised anyway near the temperature in the 3 to 4.5 m deep ground around them. So it was necessary to add more pipe circuits to thee 6 already being fed by the water pump for the heat collector system. The area available for this is only the 40 to 50 square meters of the south terrace, so it has to be three relatively short and shallow circuits at a depth of only 60 cm and lengths of 15 to 30 meters.

But a physicist knows how to improve efficiency in close quarters. A 6 cm layer of heavy duty styrodur insulation below the pavement stones will prevent the loss of heat to the surface so the heat aborbed by the new pipes has to come from deeper ground. Scrap lightning rod material is aluminum and the third best electricity and HEAT conductor known to physicists. But alas, aluminum corrodes notoriously quickly if buried in the ground, unless it is sprayed with a paint with zinc powder in it. So by spraying the scrap with this and wrapping it around the plastic pipes and driving the ends into the ground the heat can be drawn out of a large volume of earth around the pipes and improve the heat gradient from the more remote earth and keep the ground immediately around the pipes warmer, hence improving the heat transfer through the pipe walls.

Next winter will let me know how much warmer than 6° C the water returning from the heat collector pipes is.

My guess is 8° or 9° C combined with a reduction of electric power needed to heat the house, perhaps 10 % less.

The picture shows, where the two extension pipes for the blind fittings come out of the concrete ceiling of the chamber

where the ends of the original 6 circuits of the heat collector pipes are connected.

Each of these two pipes is connected here with two T fittings to form the three new loops in the collector system.